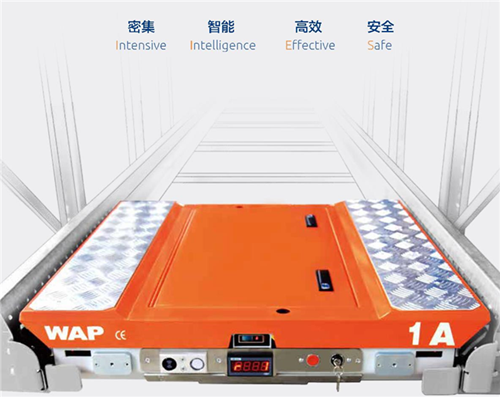

Pallet Shuttle System for Compact Storage

Pallet Shuttle System for Compact Storage

| Payment Type: | L/C, T/T |

|---|---|

| Min. Order: | 1 |

| Productivity: | 1000 Units Per Year |

|---|---|

| Place of Origin: | Shanghai |

| Supply Ability: | 1000 Units Per Year |

Basic Info

Model No.: SR 90

Product Description

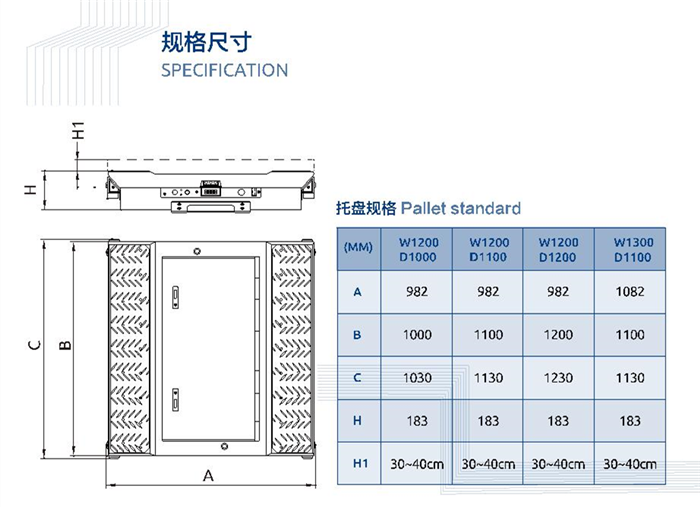

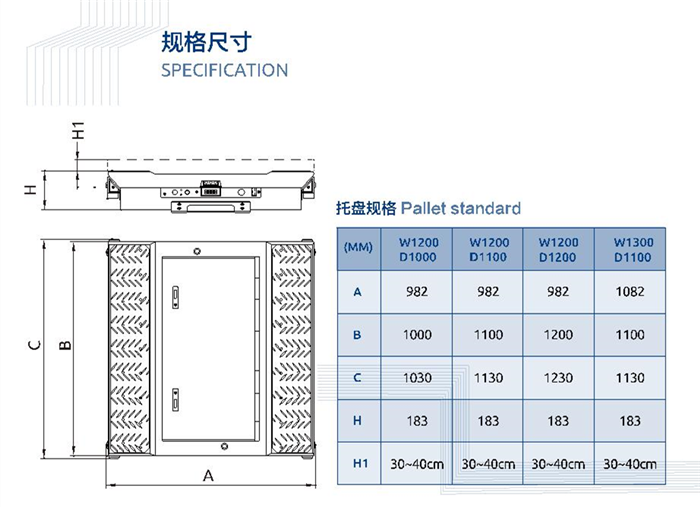

Model NO.: SR 90 Material: Steel Type: Compact Storage Height: 180mm Closed: Closed Serviceability: for Special Purpose Specification: 1200*1000 STANDARD HS Code: 84798992 Usage: Industrial Structure: Remote Controll Mobility: Mobile Weight: 500kg-1500kg Development: New Type Trademark: WAP Origin: Shanghai Product Specifications:

Shuttle racking, is a deep lane storage and retrieval system. The Pallet Shuttle System consists in a specific rack and a mobile shuttle. This shuttle is a self-powered device that runs on rails in the storage lanes for the loading and unloading of pallets. It is transported to its location at the

front or the back of a lane (in case of open back side) by a standard forklift. Once at its home position, the shuttle performs the loading and unloading tasks without any human intervention.

These tasks are instructed by the fork lift driver using a remote control. Once the tasks are completed the shuttle returns to its home position and is then ready to be transported to a new location for a new task.

By introducing more shuttles into a racking system, the performance will increase. The system can be used for new installations as well as for refurbishments, and is independent from the number and the depth of the lanes. The systems is widely used in food, FMCG, Cold chain logistic area, etc.

2. Clear benefits and advantages: A shuttle system offers highest possible density storage and is considered the best solution amongst not fully automated systems The system is semi-automated and works in combination with a fork lift truck. While the shuttle transports the load within the racking, the fork lift driver is free to work elsewhere, thus he is optimizing his working time. Compact storage of another article (SKU) on every lane. Ability to handle the pallets FIFO and LIFO. And the possibility to change at every time. Both can be available in the same block. What we call 'Maximum Flexibility'

2. Techincal Specifications:

Standard configeration:

3. Shuttle operational requirements

Pallet

For a good operation and the shuttle is a moving transport device, a good quality pallet is required. The pallet surface should be closed (no mesh patterns), unless stated otherwise. Wooden pallets of good quality, allowing the span between the 2 pallet-rails, with a maximum pallet deflection of 20mm The pallet and/or load have a fully closed strip in the middle for the detection of the sensors Not acceptable or to be tested for approval: Damaged pallets Pallets with too high deflection Pallets with an open bottom construction Containers and metal support structures Ambient conditions Operating temperature: from -30°C to +35°C Relative humidity: max 80% Shuttle better always remains in the cold-store environment Before switching on the power again the shuttle must be dry (no condensation) Not acceptable:

· Dusty, sandy, humid, combustible,… environments

4. Warehouse conditions/Cold Store Keep the shuttle always INSIDE the Cold Store But charge the batteries always OUTSIDE the Cold Store

charge only after warming up to normal temperature So in 3 shift applications best to use 3 battery packs : 1 working in the shuttle

1 warming up

1 charging in the battery station. Battery and shuttle must be completely dry before connecting For existing Cold Store Rooms check for condensation or icing on rails, floors For NEW Cold Store Warehouses check if a intermediate area is foreseen between ambient and frozen zone, humidity around a frozen storage zone is prohibited. 5. RFQ Documents:

Before you send us your requirement for quotation, please prepare the following information: Warehouse layout CAD drawings if available. Pallet size, entry side, width, depth, height of goods. Loading weight per pallet. Clear height of the warehouse Your forklift information, working aisles width and max. reaching height. Your intra logistic flow within the warehouse.

Contact us if you need more details on Radio Shuttle. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pallet Shuttle、Pallet Runner. If these products fail to match your need, please contact us and we would like to provide relevant information.

Shuttle racking, is a deep lane storage and retrieval system. The Pallet Shuttle System consists in a specific rack and a mobile shuttle. This shuttle is a self-powered device that runs on rails in the storage lanes for the loading and unloading of pallets. It is transported to its location at the

front or the back of a lane (in case of open back side) by a standard forklift. Once at its home position, the shuttle performs the loading and unloading tasks without any human intervention.

These tasks are instructed by the fork lift driver using a remote control. Once the tasks are completed the shuttle returns to its home position and is then ready to be transported to a new location for a new task.

By introducing more shuttles into a racking system, the performance will increase. The system can be used for new installations as well as for refurbishments, and is independent from the number and the depth of the lanes. The systems is widely used in food, FMCG, Cold chain logistic area, etc.

2. Clear benefits and advantages: A shuttle system offers highest possible density storage and is considered the best solution amongst not fully automated systems The system is semi-automated and works in combination with a fork lift truck. While the shuttle transports the load within the racking, the fork lift driver is free to work elsewhere, thus he is optimizing his working time. Compact storage of another article (SKU) on every lane. Ability to handle the pallets FIFO and LIFO. And the possibility to change at every time. Both can be available in the same block. What we call 'Maximum Flexibility'

2. Techincal Specifications:

| Items | DATA | Items | DATA |

| Loading capacity | ≤1500KG | Rated Voltage | 26v |

| Speed without load | 1.1 m/s | Battery Duration | ≥8h |

| Speed with load | 0.8 m/s | Remote range | 100m |

| Acceleration without load | 0.8 m/s2 | Charging time | 3h/85% |

Standard configeration:

| Items | Name | Specification | Quantity | |

| Standard configuration | Shuttle main body | W****D*** | 1 SET | |

| Lithium Battery | 26V/60AH | 1 SET | ||

| Battery Charger | 29.4V | 1 PCS | ||

| Remote controller | T60TX-15DML | 1 PCS | ||

| Lock of battery compartment | C19*20L | 1 SET | ||

| Expanded configuration | WMS, AUTOMATIC INVENTORY,PAD | |||

3. Shuttle operational requirements

Pallet

For a good operation and the shuttle is a moving transport device, a good quality pallet is required. The pallet surface should be closed (no mesh patterns), unless stated otherwise. Wooden pallets of good quality, allowing the span between the 2 pallet-rails, with a maximum pallet deflection of 20mm The pallet and/or load have a fully closed strip in the middle for the detection of the sensors Not acceptable or to be tested for approval: Damaged pallets Pallets with too high deflection Pallets with an open bottom construction Containers and metal support structures Ambient conditions Operating temperature: from -30°C to +35°C Relative humidity: max 80% Shuttle better always remains in the cold-store environment Before switching on the power again the shuttle must be dry (no condensation) Not acceptable:

· Dusty, sandy, humid, combustible,… environments

4. Warehouse conditions/Cold Store Keep the shuttle always INSIDE the Cold Store But charge the batteries always OUTSIDE the Cold Store

charge only after warming up to normal temperature So in 3 shift applications best to use 3 battery packs : 1 working in the shuttle

1 warming up

1 charging in the battery station. Battery and shuttle must be completely dry before connecting For existing Cold Store Rooms check for condensation or icing on rails, floors For NEW Cold Store Warehouses check if a intermediate area is foreseen between ambient and frozen zone, humidity around a frozen storage zone is prohibited. 5. RFQ Documents:

Before you send us your requirement for quotation, please prepare the following information: Warehouse layout CAD drawings if available. Pallet size, entry side, width, depth, height of goods. Loading weight per pallet. Clear height of the warehouse Your forklift information, working aisles width and max. reaching height. Your intra logistic flow within the warehouse.

Contact us if you need more details on Radio Shuttle. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pallet Shuttle、Pallet Runner. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Pallet Shuttle System

Premium Related Products

Other Products

Hot Products

Shopping Folding Cart With Flexible Wheelswarehouse storage removable case rack for tool & materialcnc tool storage cabinetsMedium Duty Storage Boltless RackHot Sell China Supply One side Supermarket Display ShelfHot Sell Stainless Wire Mesh Cage With WheelsPowder Coating Drawer Type Mould Storage RackSystem Iron Storage Rolling Rackwarehouse heavy duty cable rackprofessional warehouse steel platform mezzanine rackingCompetitive Price Stainless Cantilever Storage Rackstandard euro substitution of wood and plastic palletMedium Duty System Racking And Shelving PalletMetal System Roll Storage RackClad Drive In Logistics RackVery Narrow Aisle Factory Use Heavy Duty Racking System